Believe it or not, there’s A LOT that goes into a roof besides shingles.

In fact, when Roofing and Beyond schedules a delivery for a new roof replacement job, up to (15) different items can be included on each order we place from our local supplier.

Here’s a list of the (9) products required on every roof replacement job (in order of installation):

1) Drip Edge

Drip edge is a metal (usually aluminum) flashing that’s installed along the roof edges.

The purpose of drip edge is to protect the fascia and also to ensure water ends up landing in the gutter, instead of behind it.

2) Ice & Water Shield

Ice & Water Shield is a rubberized ‘peel and stick’ underlayment that protects the most vulnerable areas of your roof from damage caused by ice dams and wind driven rain.

Roofing and Beyond installs ice and water shield: 6’ at the eaves, 3’ in valleys, and also around roof penetrations including vent pipes, chimneys, and skylights.

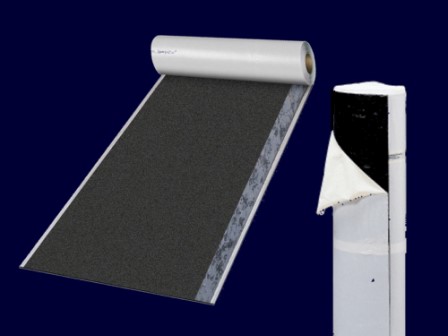

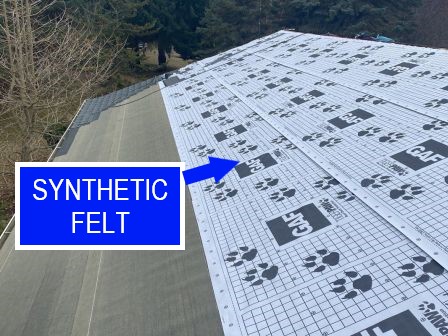

3) Felt / Synthetic Felt

Felt covers the rest of the roof after the ice and water shield is installed.

Felt paper or ‘tar paper’ was the industry standard prior to synthetic felt’s arrival in the early 2000’s.

A good quality synthetic felt is waterproof, tear resistant and doesn’t wrinkle when it gets wet. These benefits can come in handy when inclement weather shows up out of nowhere or if the new roof cannot be completed in one day.

4) Starter Shingles

Starter shingles are installed on the eave AND rake edges to help reduce the risk of water infiltration and also to prevent shingles from blowing off during high winds.

The properly positioned adhesive strip bonds the new shingles together creating a tight seal with a wind warranty of up to 130 MPH!

5) Flashing

Roof flashing(s) refers to thin pieces of material used to prevent water infiltration at roof/wall intersections and around roof penetrations.

Metal roof flashings made of aluminum are standard on residential shingled roofs, although lead, copper and galvanized steel can also be used.

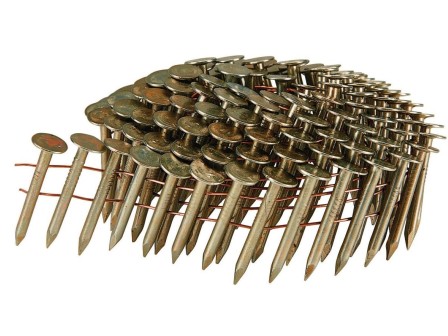

6) Nails

Instead of listing shingles here, see my prior blog post listing the (10) Different Roofing Shingles Available Today.

Most shingle manufacturers recommend a minimum of (4) nails per shingle but in order to qualify for the maximum wind warranties, (6) nails per shingle is typically required.

High quality roofing nails (like the ones used by Roofing and Beyond) are made from galvanized steel, coated with zinc for long term rust prevention and minimum 1 ¼” in length.

7) Attic Ventilation (Exhaust)

A well ventilated attic is constantly removing excess heat and moisture build up which helps reduce energy costs, fight ice dams, and extend the life expectancy of your roof.

Different types of exhaust vents should NOT be mixed on the same roof because they will pull from each other (path of least resistance) and short circuit the ventilation system.

The two most common types of exhaust ventilation used for a roof replacement project are ridge vent and can vents (aka: box vents or louver vents).

8) Hip and Ridge Shingles

Hip and ridge shingles (aka cap shingles) are used where two different roof slopes meet.

Less expensive options should be avoided but are still used by contractors who cut corners.

Higher quality cap shingles:

• Won’t deteriorate prematurely

• Perfectly match the main roof color

• Seal properly and lay flat due to the stronger adhesive seal

*Most shingle manufacturers require specific hip and ridge shingles be used in order to warranty the entire roof!

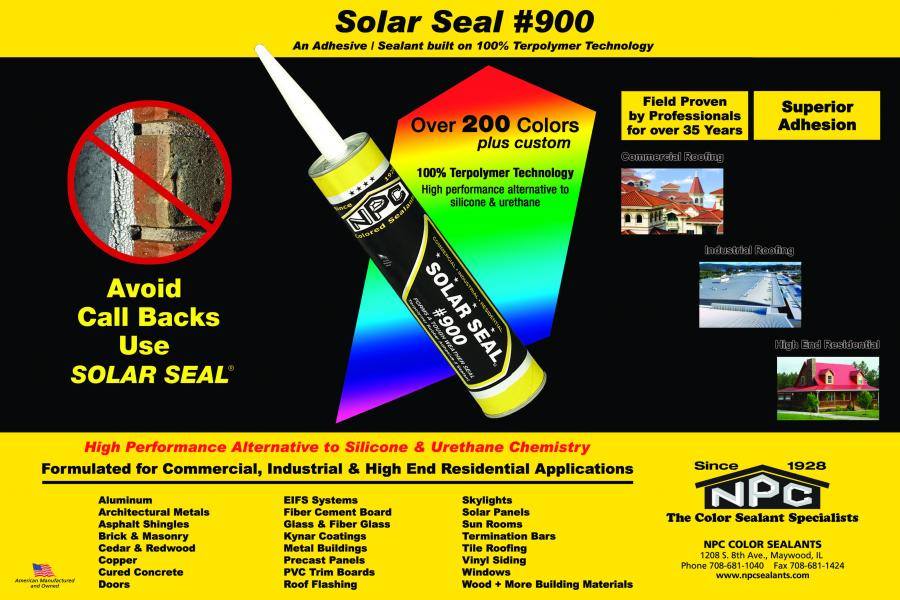

9) Caulk

Caulk is used to add the finishing touch on all roofing projects.

In areas with daily changing climates, NPC Solar Seal #900 is what the professionals use because it creates a water-proof barrier and stays flexible.

Leave a Reply

I’m getting ready to replace my roof soon and this article was VERY helpful, thank you!